- Software DevelopmentIT Consulting & DesignAI & Data SolutionsQuality AssuranceTeam & Resource SupportBusiness Support Services

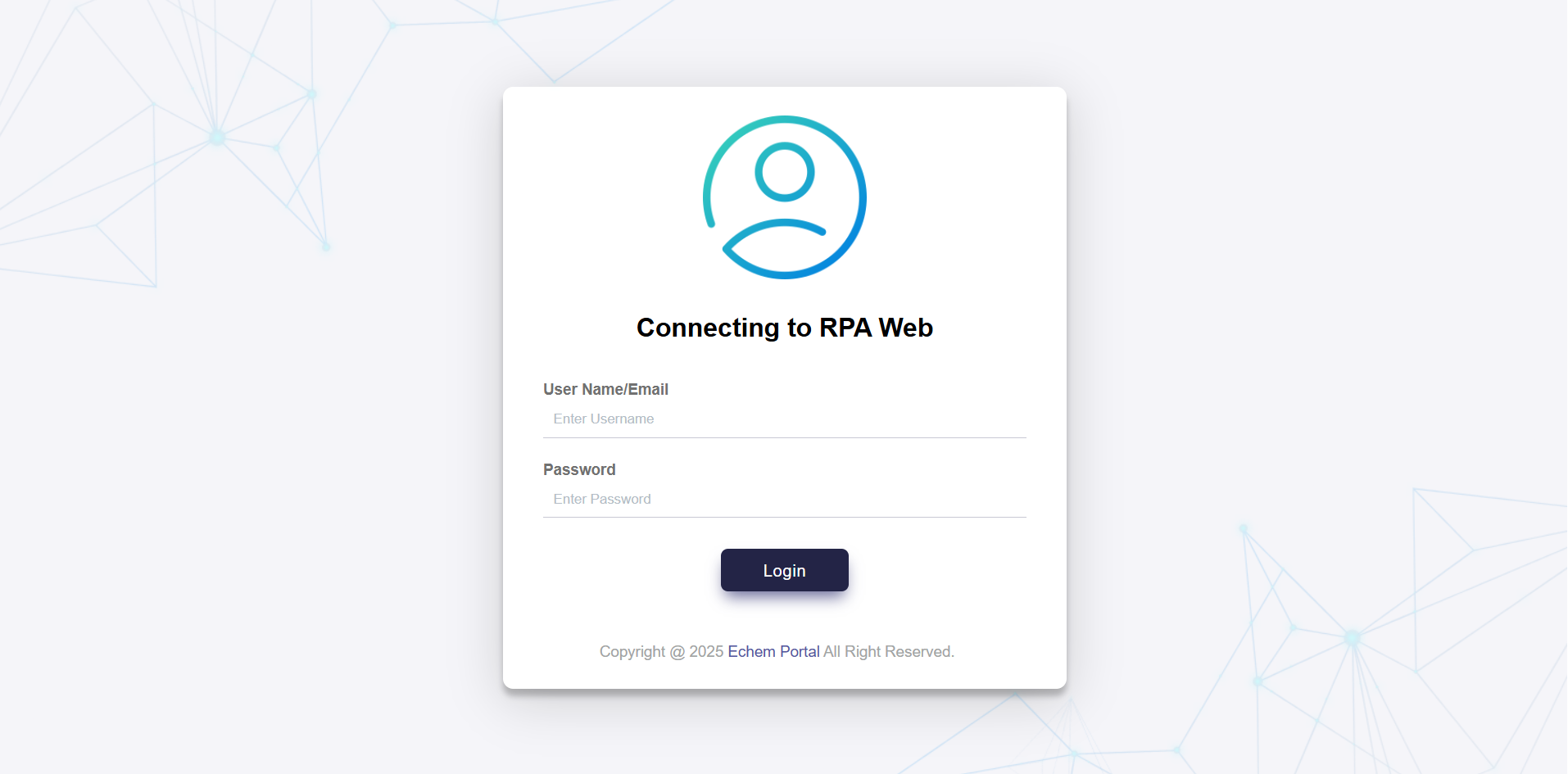

The Routine Process Automation (RPA) platform is an internal system developed to handle end-to-end product data workflows, including file-based supplier data ingestion, supplier website scraping, data cleaning and transformation, and importing cleaned data into the internal SQL Server (SSMS) database.

The Routine Process Automation (RPA) platform is an internal system developed to handle end-to-end product data workflows, including file-based supplier data ingestion, supplier website scraping, data cleaning and transformation, and importing cleaned data into the internal SQL Server (SSMS) database.

The Internal Automation Team serves a data-driven organization managing large-scale product data pipelines for research, sourcing, and market intelligence.

Faced with increasing supplier and product volumes, the team required an intelligent, scalable automation system to eliminate manual scraping, data cleaning, and import processes, enabling operational efficiency and consistency across workflows.

Pharmaceutical, Chemical, Data & Research Services, Enterprise Automation Solutions

Enterprise Internal Automation, Robotic Process Automation Ecosystem (RPA), and Data Cleaning & ETL Pipelines.

Comprehensive solutions designed to enhance user experience and drive business growth.

Allows users to upload Excel/TXT supplier files, select the relevant supplier module, and choose the processing server. This ensures files are routed correctly and processed efficiently.

Supports standard, VPN, and Tor-based clients, enabling resilient scraping while accessing region-restricted supplier websites and rotating IPs for reliable data collection.

Integrates with a centralized FileManager API to manage all input and output files systematically, ensuring documents are traceable, organized, and securely stored.

The middleware server dynamically schedules and distributes scraping and processing tasks across clients based on availability and task type, maximizing system throughput.

Automatically cleans, standardizes, and transforms scraped data before importing it into SQL Server, ensuring data consistency and readiness for analysis and operations.

Provides real-time visibility into the status of each automation task, detailed logs for every step, and progress tracking via the RPA web portal, ensuring transparency and easy troubleshooting.

Supports image generation, email validation, and chemical information enrichment using PubChem, expanding the system's capabilities beyond basic scraping and importing.

Users can view and download cleaned and processed output files directly from the platform, which simplifies integration and integration into downstream workflows.

We identified key pain points and developed targeted solutions to transform the resort's digital presence.

The challenge was the absence of a centralized system for managing scraper pipelines and logs.

Inconsistent supplier file formats require dynamic processing logic.

Accessing region-restricted supplier websites requires the use of a VPN or Tor.

Synchronization of files and logs between clients and servers.

We ensure data traceability during the importation of cleansed data.

Scalability challenges with onboarding new suppliers and modules.

We designed a modular, scalable RPA architecture using Flask, SocketIO, and Docker.

Built a middleware server to intelligently schedule and route tasks to appropriate clients.

Integrated VPN and Tor-based scraping for region-specific data extraction.

Enabled PubChem-based chemical data enrichment.

Developed a centralized FileManager API for managing input/output files.

Built a log-tracking system for complete visibility and auditing.

Developed a Cleaner Engine to convert raw scraped data into import-ready formats automatically. A DataUploadClient has been added to securely import cleaned data into SQL Server.

Visual highlights showcasing the transformation and key features of the new website.

Let's discuss your project and create a custom web application that drives your business forward. Get started with a free consultation today.

Reduced manual data entry and processing time by over 80%.

Reduced manual data entry and processing time by over 80%.

Enabled handling of 100+ suppliers in parallel.

Improved data accuracy and consistency across product records.

Centralized monitoring and traceability of all automation requests.

Scalable system for onboarding new modules and suppliers with minimal developer intervention.

Enhanced data enrichment for research and analysis with chemical info integration.